Meta Description: Для цемента, сухих строительных смесей и многого другого, Wanlin Packaging предлагает больше, чем просто мешки — мы предлагаем надежность, инновации и индивидуальные решения. Ознакомьтесь с нашим полным ассортиментом от тканых полипропиленовых мешков до современных клапанных мешков.

В требовательном мире строительных материалов ваша упаковка является последним гарантом качества продукции и первым представителем вашего бренда. Она должна быть достаточно прочной, чтобы выдерживать строгую логистику, достаточно умной, чтобы обеспечить эффективную обработку, и достаточно надежной, чтобы защитить ваш продукт от завода до конечного объекта.

В Wanlin Packaging мы прекрасно понимаем эти проблемы. Мы не просто поставщик мешков; мы ваш преданный Комплексный партнер по упаковке для цементной, сухой строительной смеси и более широкой индустрии строительных материалов. С комплексным портфелем, разработанным для удовлетворения любых потребностей, мы гарантируем, что ваше внимание остается на производстве качественных материалов, а упаковку оставляете нам.

Полный спектр решений для каждой задачи упаковки

Наша сила заключается в нашей способности предлагать правильный инструмент для правильной работы. Мы предлагаем полный спектр упаковочных продуктов, каждый из которых разработан для конкретных применений:

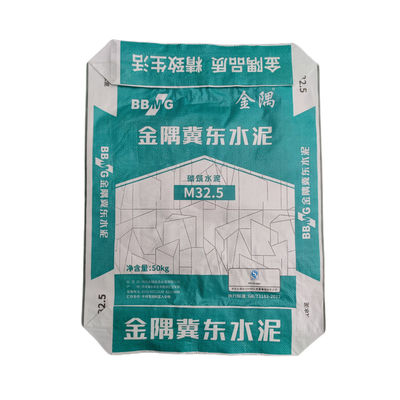

Тканые полипропиленовые мешки для цемента: Рабочая лошадка отрасли, известная своим исключительным соотношением прочности к весу и долговечностью. Идеально подходит для защиты сыпучих сухих грузов.

Бумажные мешки для цемента: Классический выбор, предлагающий хорошую воздухопроницаемость и натуральный, перерабатываемый вариант для различных применений.

МКР (мягкие контейнеры) / Биг-бэги: Наиболее эффективное решение для транспортировки и хранения больших объемов (обычно 500-2000 кг) материала, оптимизирующее вашу логистику.

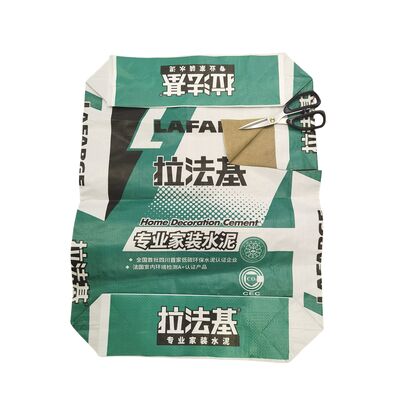

Мешки для сухих строительных смесей: Специально разработаны для защиты чувствительных смесей от влаги и обеспечения сыпучести продукта. Мы специализируемся как на открытых, так и на современных клапанных мешках для безпылевого заполнения.

Мешки Ad Star (мешки с приклеенным дном): Произведенные на точном австрийском оборудовании, эти мешки имеют запаянное дно, которое исключает отверстия от строчки, обнаруженные в традиционных мешках. Это создает превосходный барьер, обеспечивая исключительную защиту от влаги и несанкционированного доступа для высокоценных продуктов, таких как цемент премиум-класса.

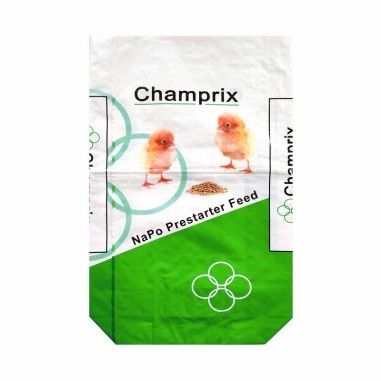

Ламинированные мешки (с внутренним слоем из полиэтилена/бумаги): Наши тканые мешки могут быть ламинированы внутренним слоем из полиэтилена или бумаги, создавая превосходный влагобарьер для самых чувствительных продуктов, таких как цемент или некоторые виды кормов.

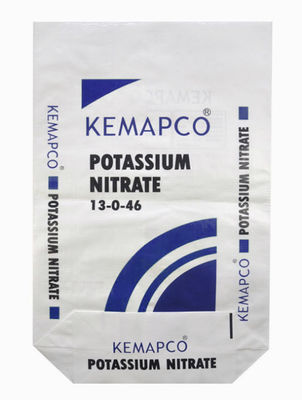

Мешки с квадратным дном и открытым верхом: Эти мешки стоят вертикально для удобства заполнения и представляют собой чистую прямоугольную форму для устойчивого паллетирования и премиального вида. Идеально подходят для широкого спектра продуктов, таких как корма для животных и удобрения, они могут быть изготовлены с внутренней полиэтиленовой подкладкой для усиленной защиты от влаги. Мы предлагаем как стандартную, так и многоцветную печать высокого разрешения для удовлетворения ваших потребностей в брендинге.

Клапанные мешки из полиэтилена с термосваркой: Разработанные для максимальной эффективности и целостности продукта, эти мешки имеют многослойную полиэтиленовую конструкцию, которая создает исключительный влагобарьер. Запатентованный клапан обеспечивает полностью герметичное, безпылевое заполнение, что делает их идеальными для автоматизированных упаковочных линий и требовательного содержимого, такого как технический углерод, пигменты, специальные химикаты и порошки высокого качества, где чистота и сухость имеют решающее значение.

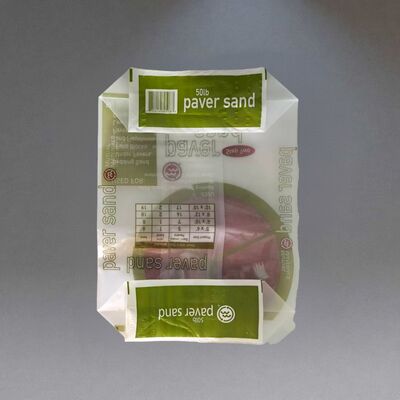

Мешки для песка: Для строительства, борьбы с наводнениями и промышленных применений, обеспечивающие надежное удержание и вес. Наши стандартные зеленые мешки для песка обеспечивают устойчивость к ультрафиолетовому излучению в течение 3-4 месяцев, в то время как наши черные мешки с техническим углеродом обеспечивают увеличенную долговечность на открытом воздухе в течение 6-7 месяцев, обеспечивая долгосрочную производительность при прямом солнечном свете.

Почему партнерство лежит в основе нашей деятельности

Мы считаем, что успешные отношения с поставщиком строятся не только на транзакциях. Они строятся на:

-

Глубоком знании отрасли: Мы говорим на вашем языке. Мы понимаем технические требования к упаковке цемента, строительных смесей, кормов и химикатов.

-

Бескомпромиссном контроле качества: От сырья до конечного шва и печати, каждый мешок производится в соответствии с высочайшими стандартами соответствия и производительности.

-

Настройке и брендинге: Ваш бренд имеет значение. Мы предлагаем многоцветную печать высокого разрешения, чтобы превратить вашу упаковку в мощный маркетинговый инструмент на полке или на строительной площадке.

-

Надежности и масштабе: Вы можете рассчитывать на нас, чтобы мы поставляли продукцию последовательно, вовремя и в соответствии со спецификациями, поддерживая ваш график производства без перебоев.

Ваше путешествие начинается здесь

Эта статья — ваше знакомство с нашими возможностями. Думайте об этом как о двери в мир опыта в области упаковки. В ближайшие недели мы углубимся в каждое решение. Мы рассмотрим технические преимущества клапанных мешков для сухих строительных смесей, экономику МКР для обработки сыпучих материалов и силу брендинга наших цветных печатных тканых мешков.

Готовы защитить свою продукцию с надежным партнером?

Не соглашайтесь на простой мешок. Сотрудничайте с компанией, которая предлагает выбор, инновации и душевное спокойствие.

Свяжитесь с Wanlin Packaging сегодня. Давайте обсудим ваши конкретные потребности, и мы направим вас к оптимальному упаковочному решению, которое уравновешивает производительность, стоимость и влияние на бренд.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!